# Longboi Assembly Guide

PLEASE DO NOT LEAVE YOUR PRINTED PRODUCT OUTSIDE OR IN A HOT, UNCONDITIONED AREA FOR EXTENDED PERIODS OF TIME.

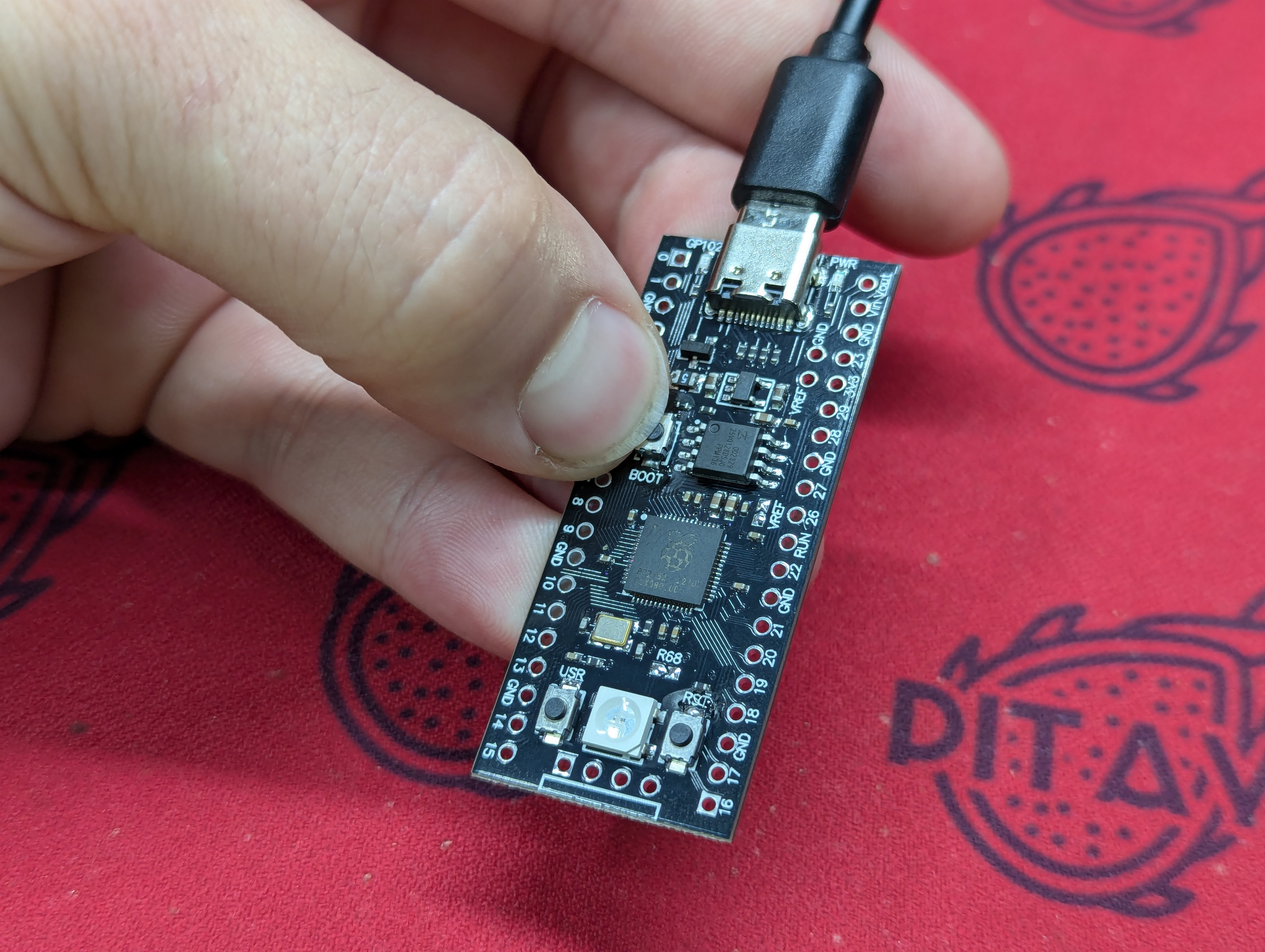

# Flash the MCU

It's important to flash the MCU before starting to make sure it works.

- Download the .uf2 file for the device from the firmware list.

- While holding the boot button, plug the MCU into the computer.

- Drag the .uf2 file into the new drive that shows up. Confirm the device shows up in VIAL after it disconnects and reconnects.

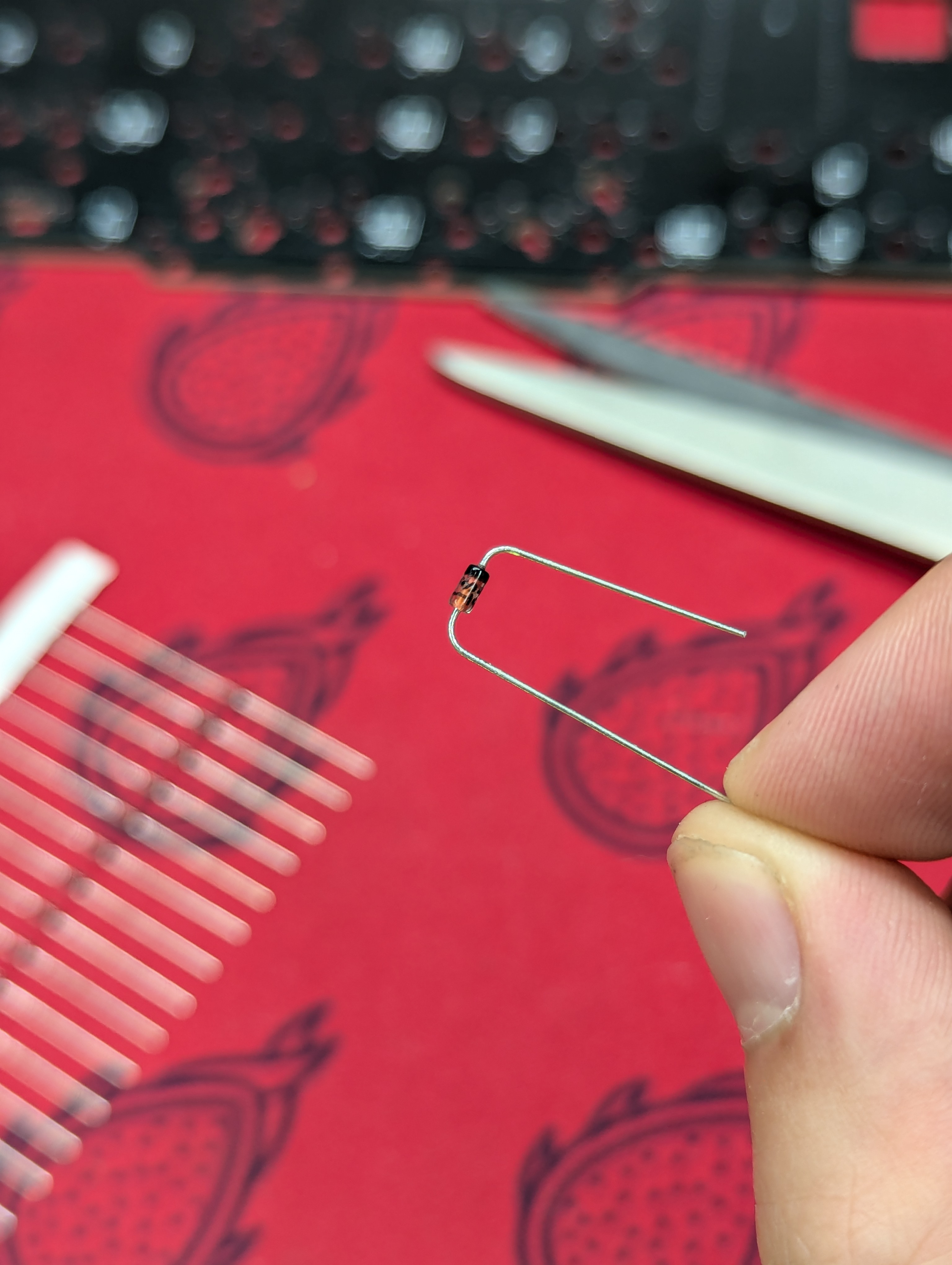

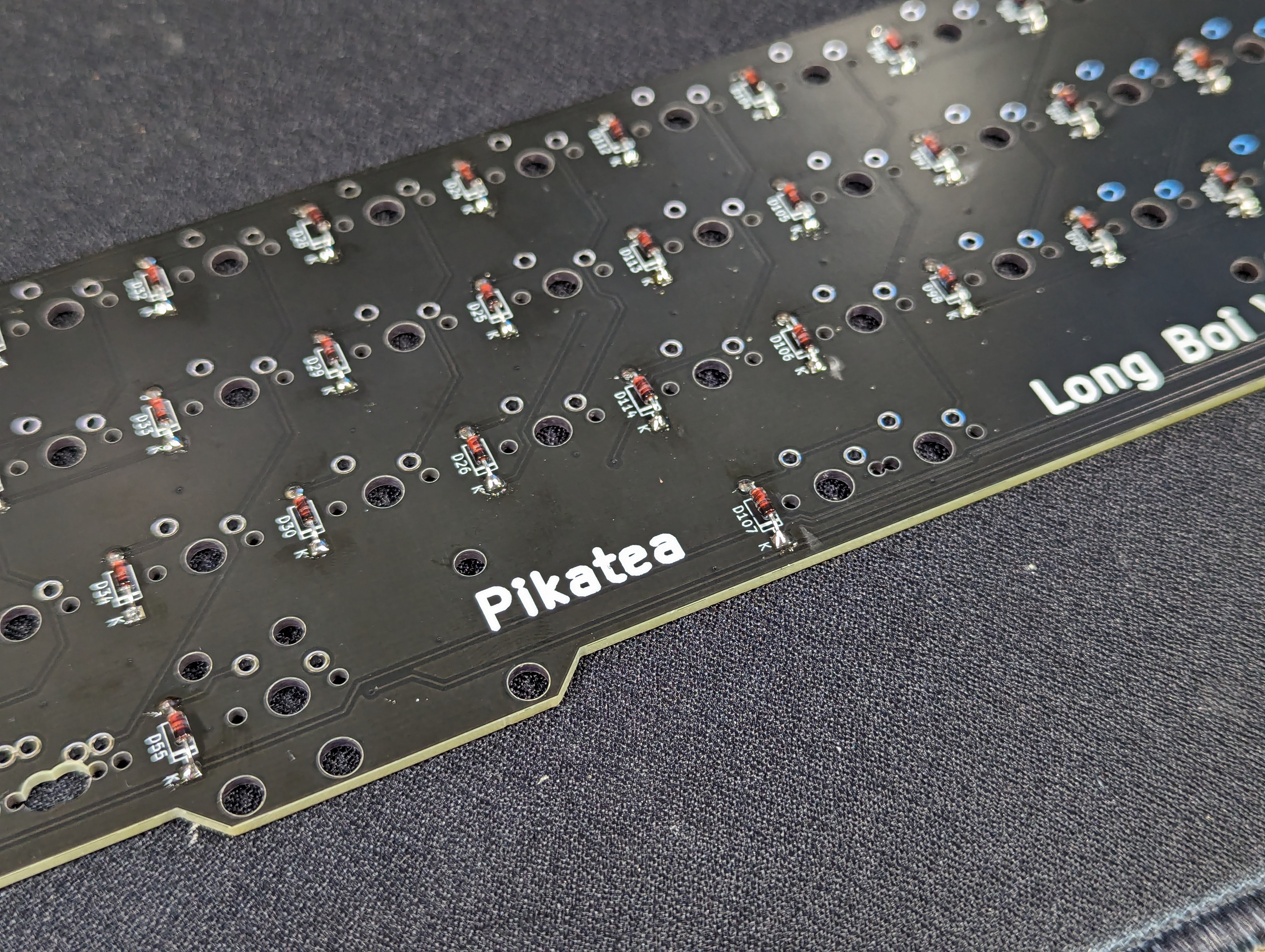

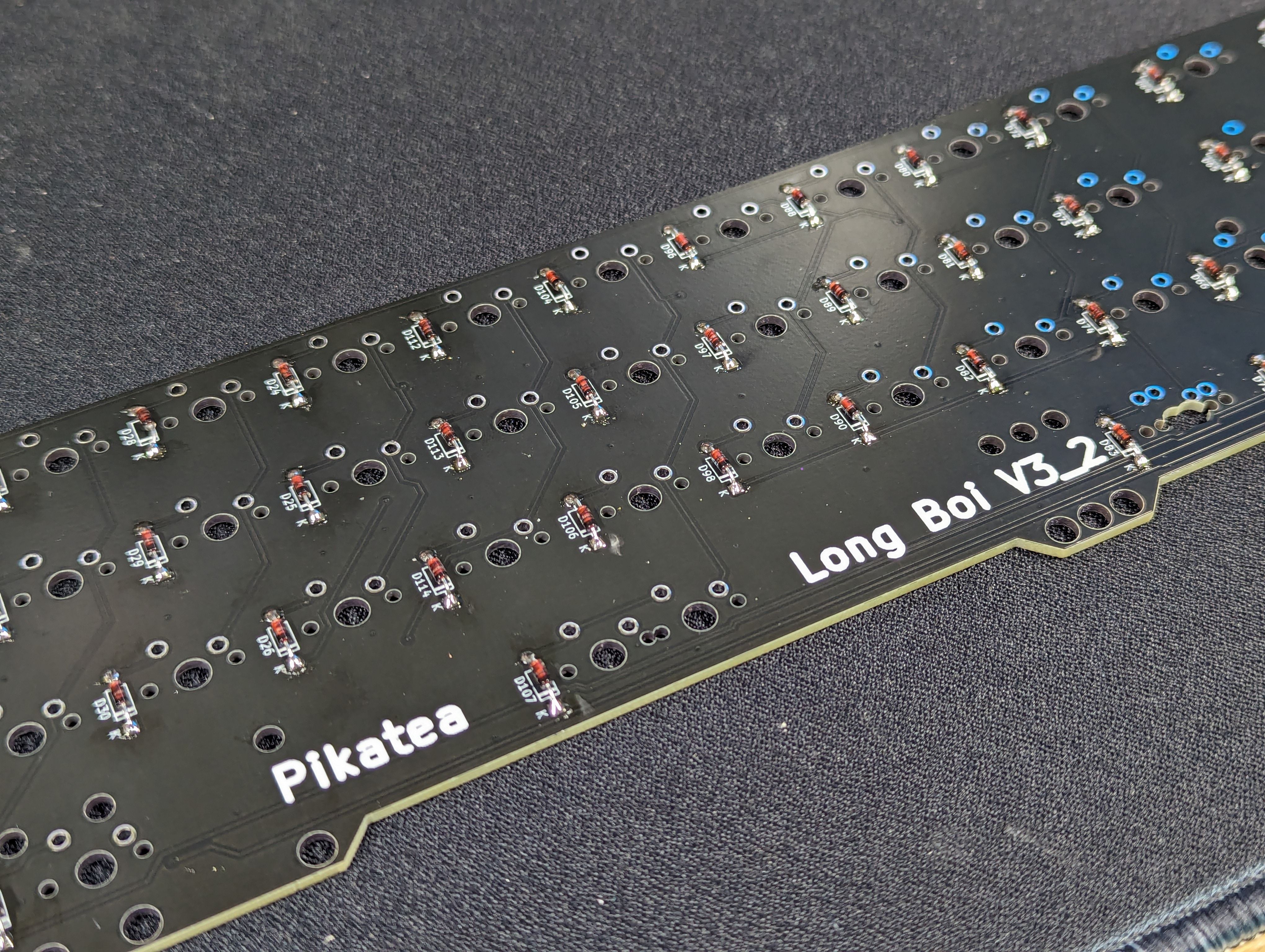

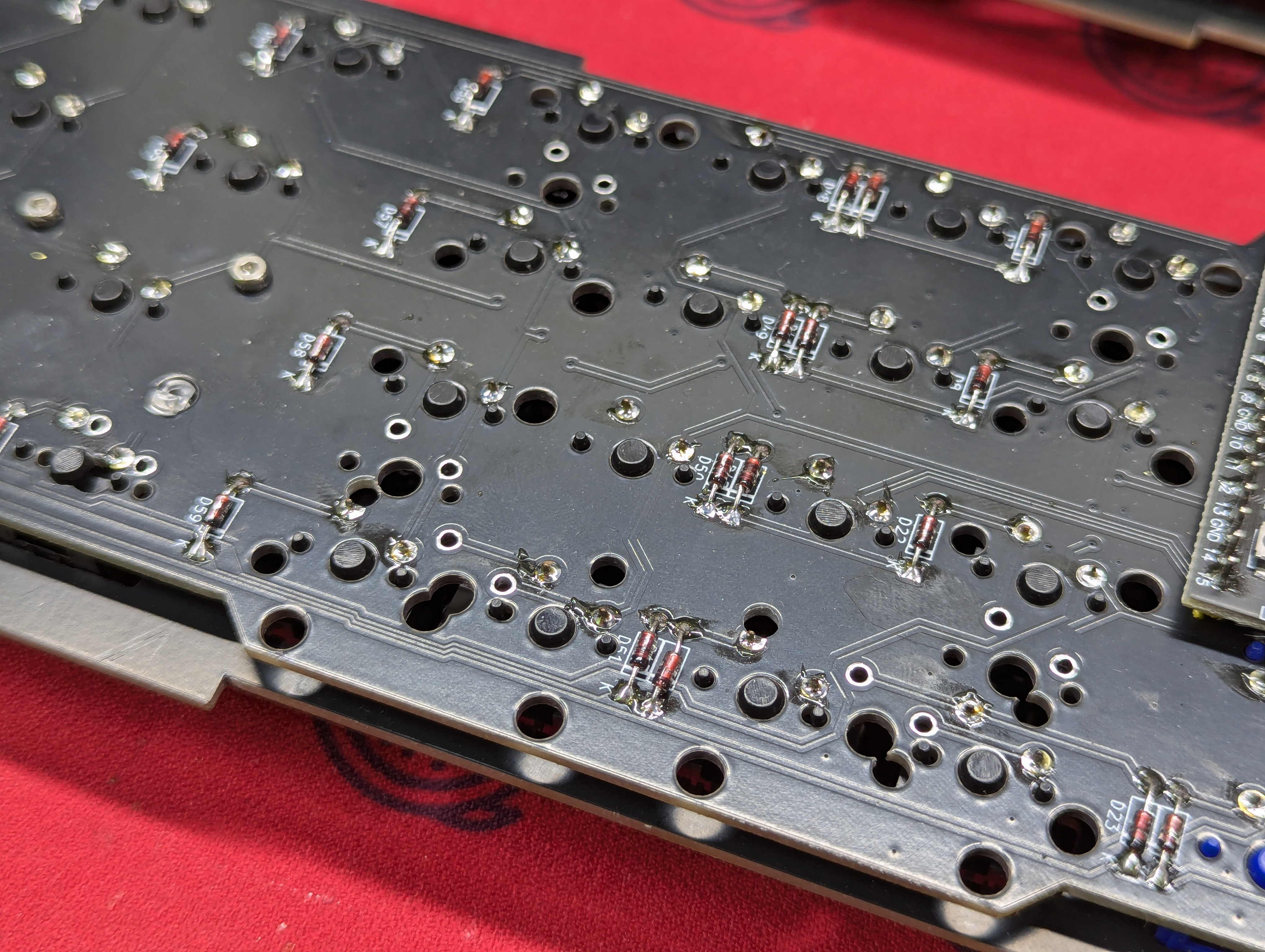

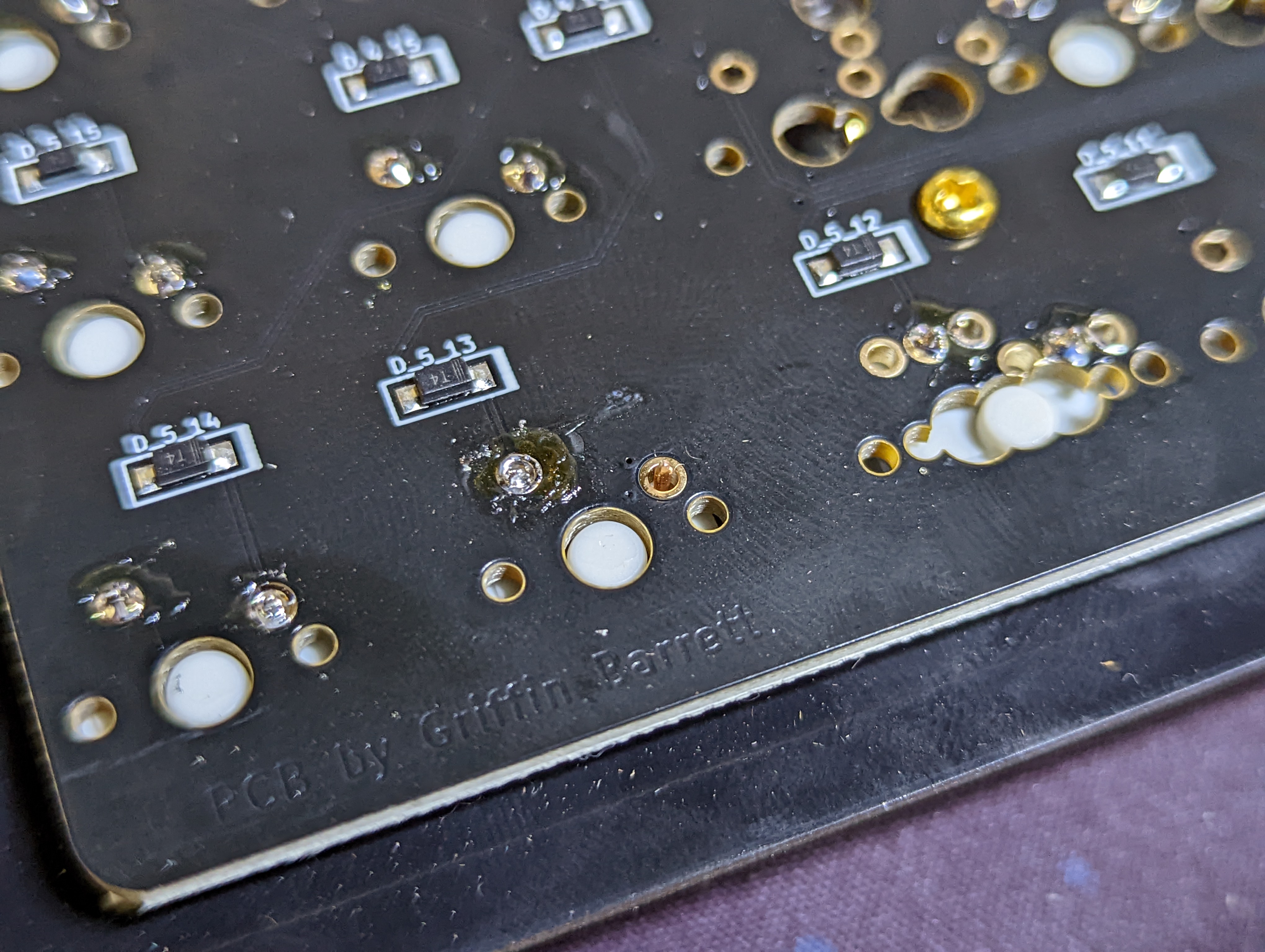

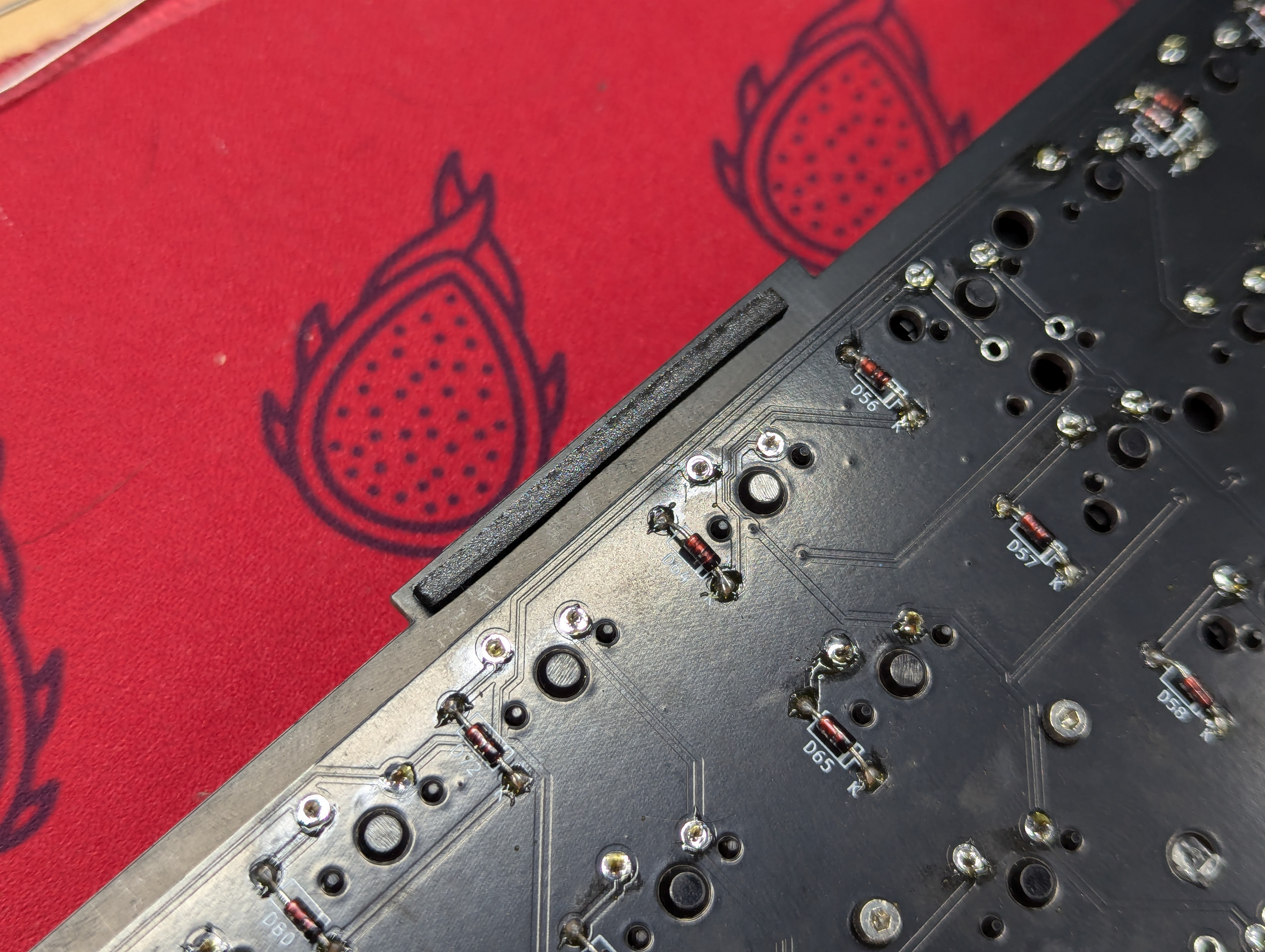

# Solder the Diodes

- Bend a diode and insert it into the PCB being careful it is the correct orientation. The black bar on the diode matches with the thicker white bar on the PCB.

- After the diode is inserted, bend the leads outwards so it stays in place. Repeat steps 1 and 2 for each diode.

- With each diode in place, Solder them to be permanently secured.

- Bend the diodes legs straight and use flush cuts to them off. Be careful not to scratch the PCB when doing this.

# Stabilizers

- Install PCB mounted stabilizers.

They usually screw in but some might clip in. Below are a few links that explain keyboard stabilizers and how to install them. You'll need a stabilizer for each key that is 2u or larger.

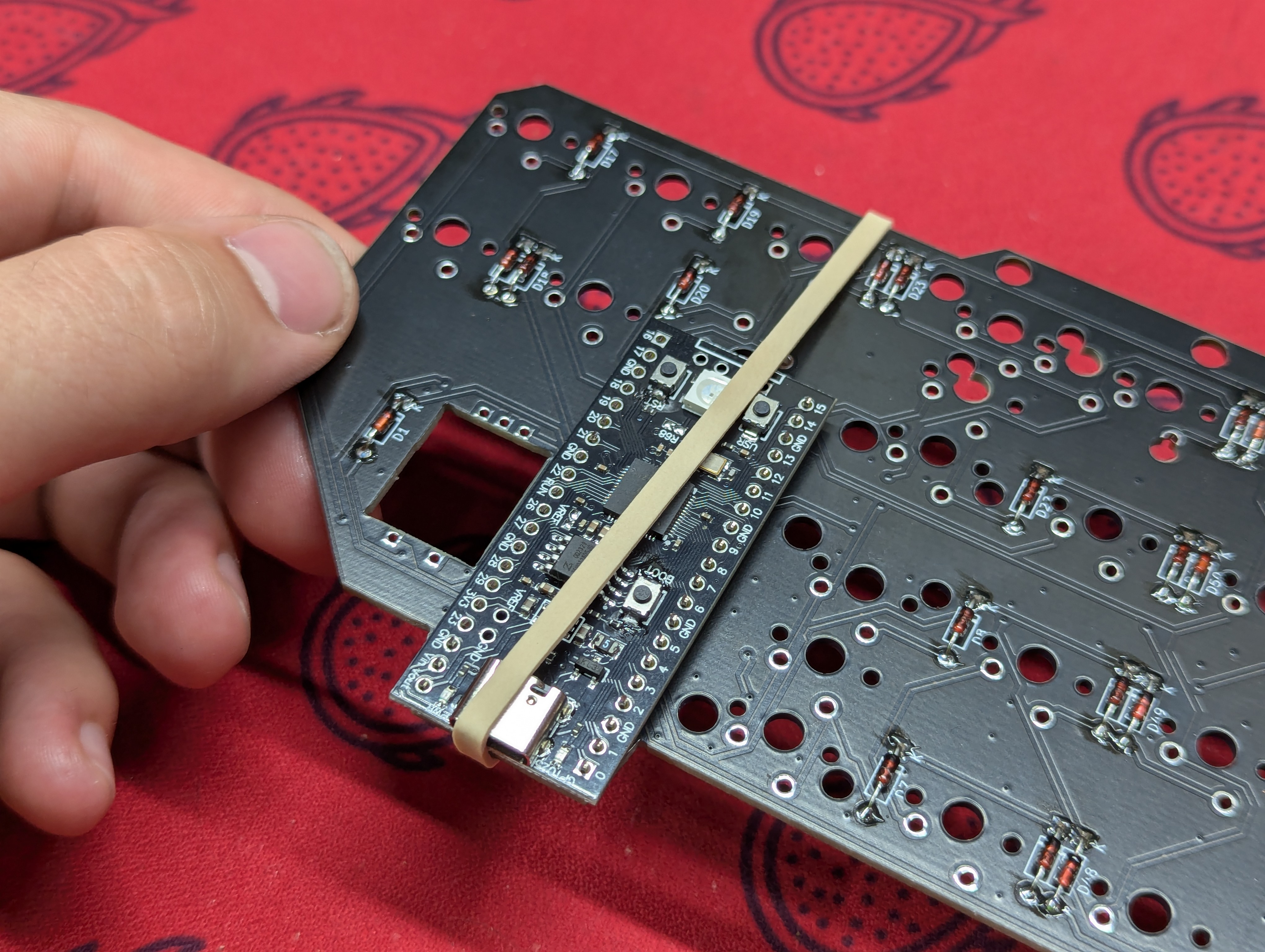

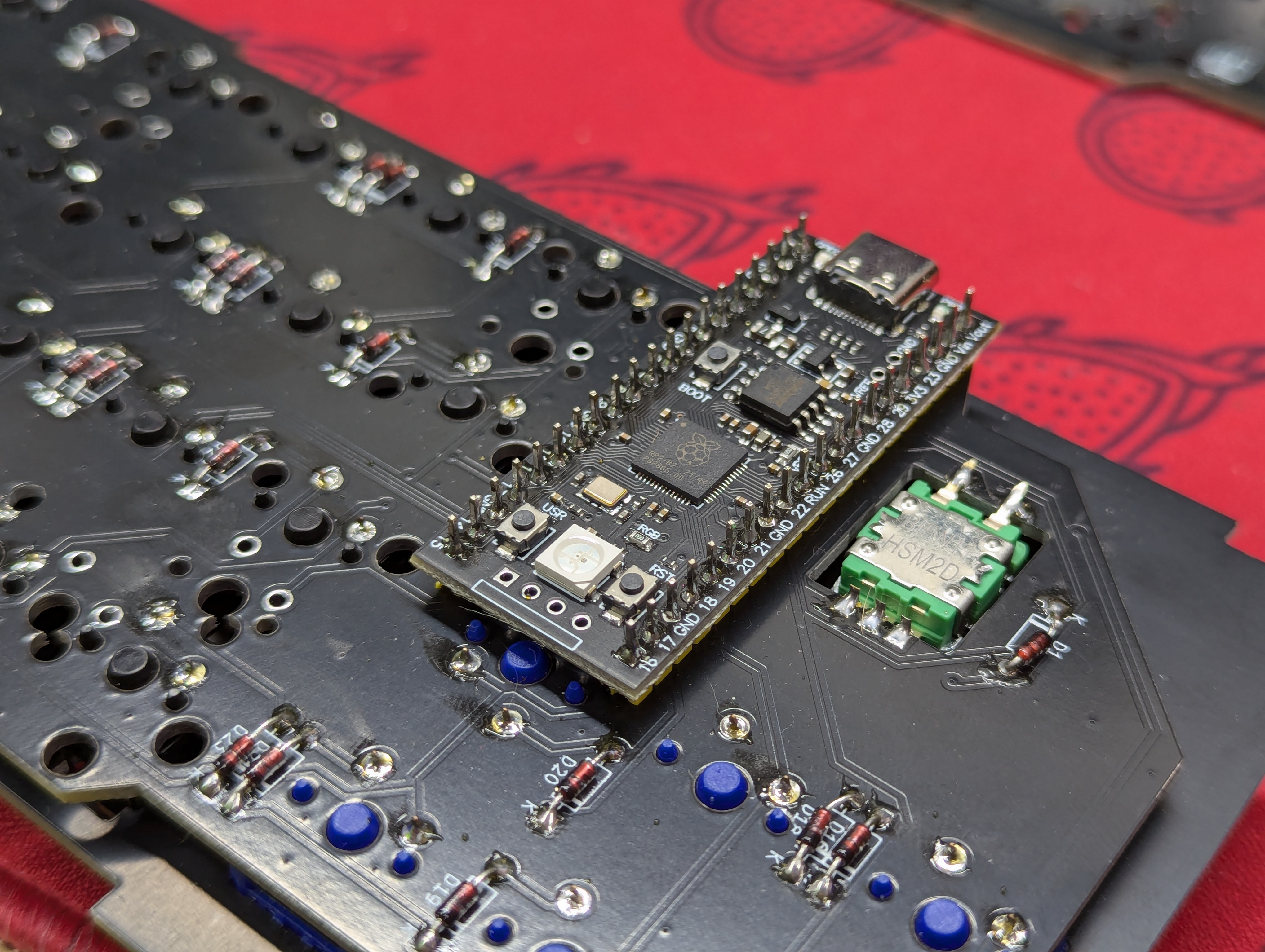

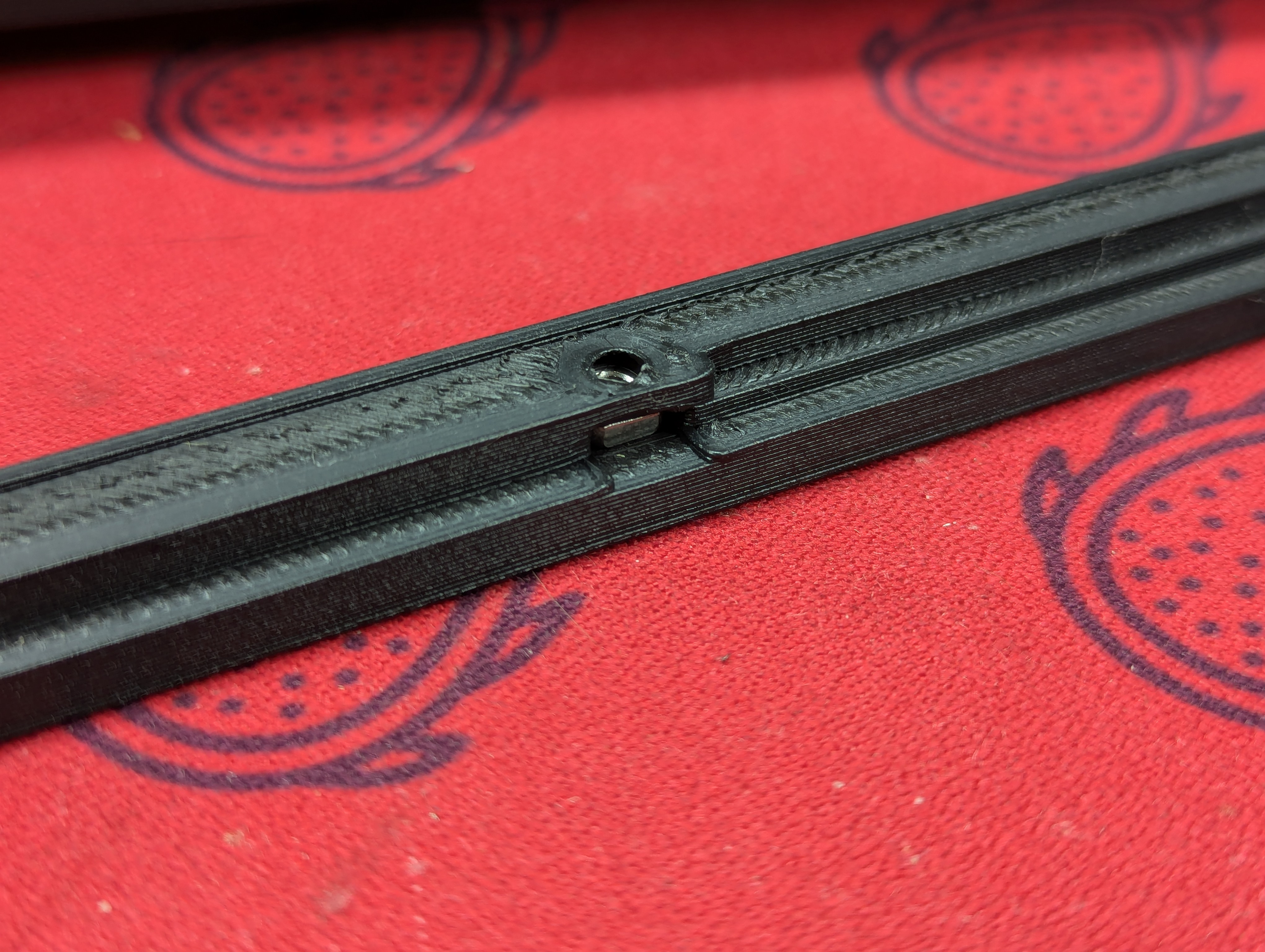

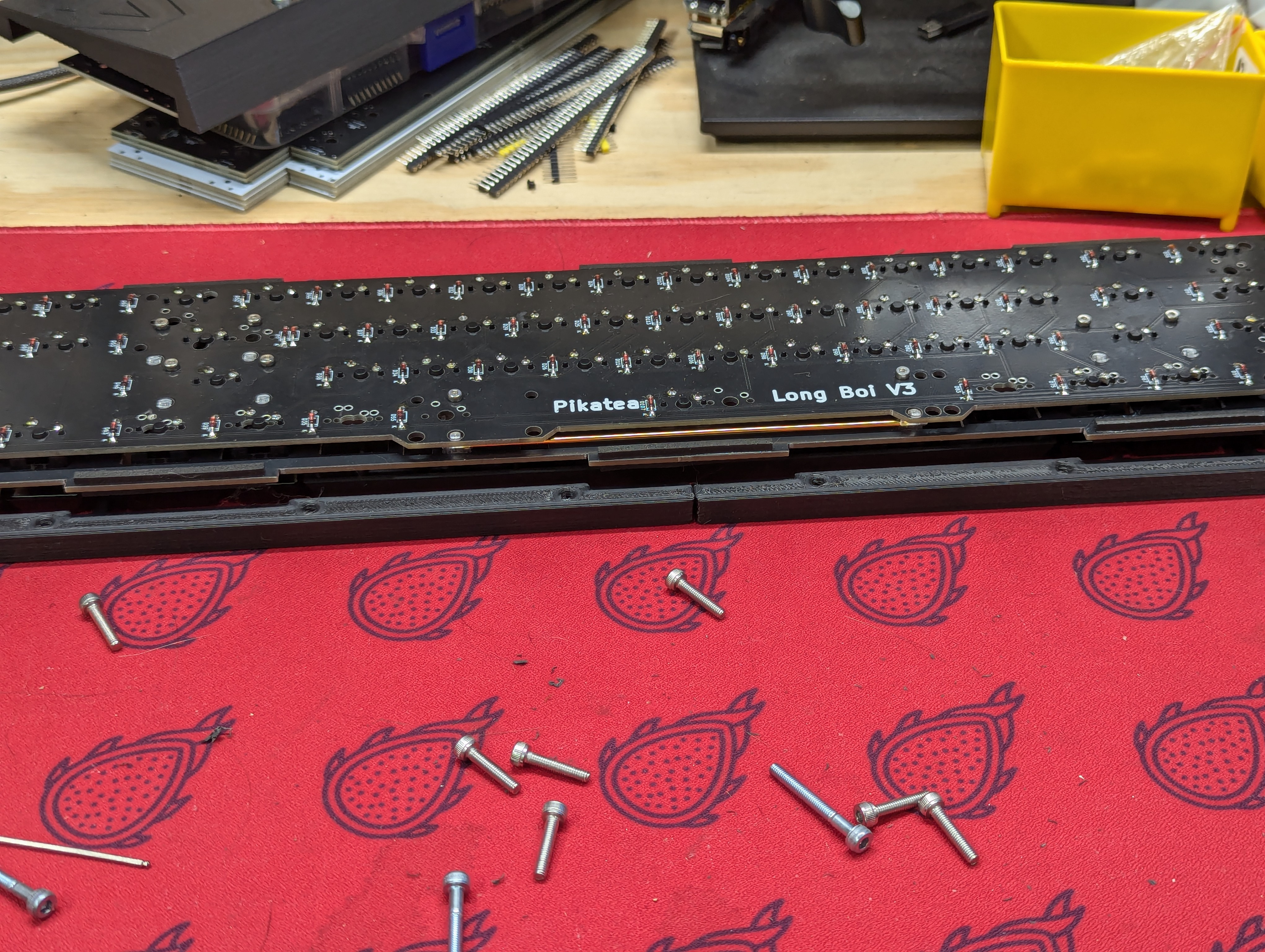

# Trim The Headers

The headers need to be trimmed or the backplate will not fit.

- Cut the longer side of the headers in half as shown. It doesn't have to be precise.

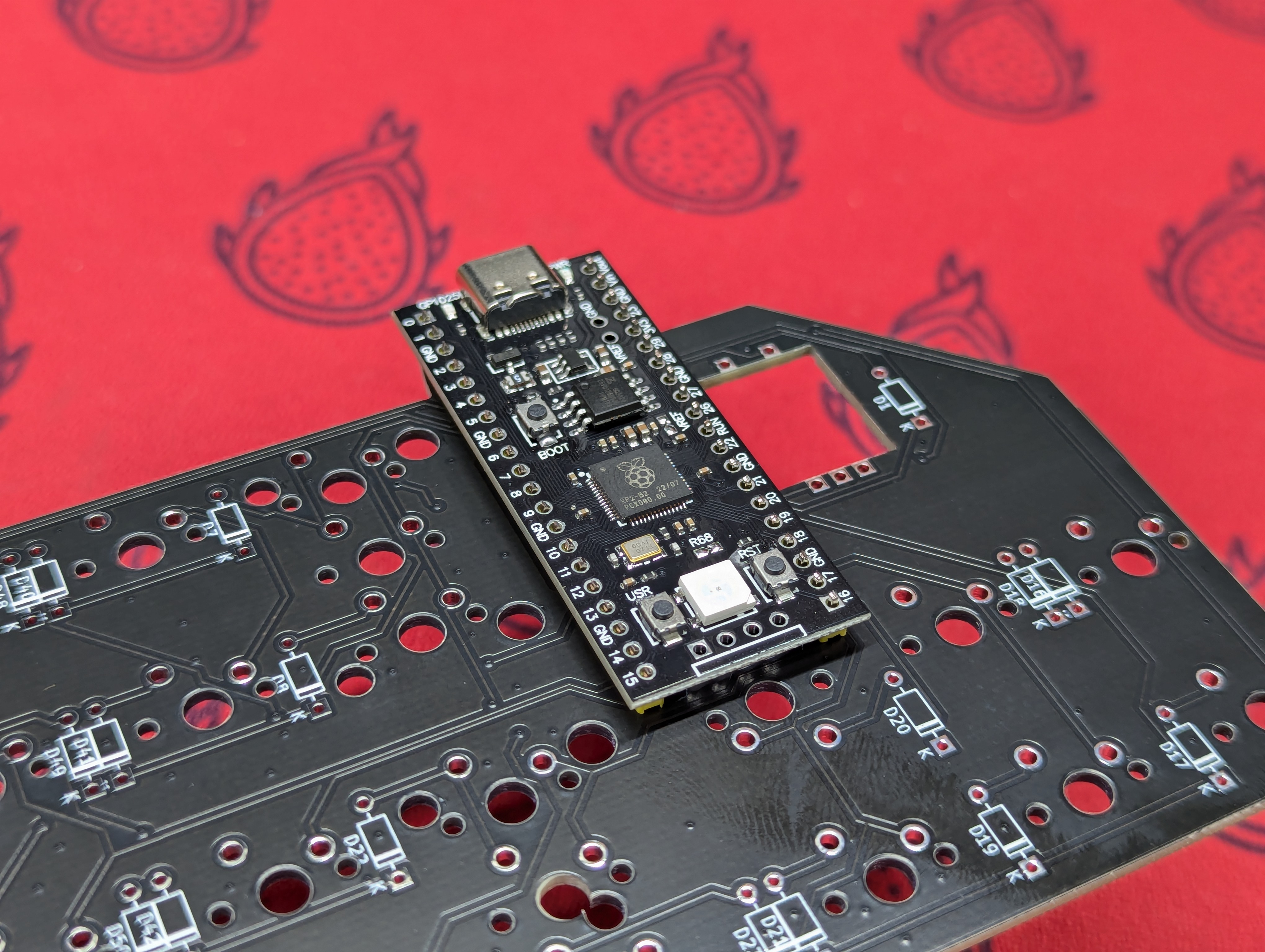

# Solder MCU

- Insert the trimmed headers into the PCB.

- Add the MCU on top.

- Use a rubber band to hold everything in place.

- Solder both sides of the headers to perminently hold everything together.

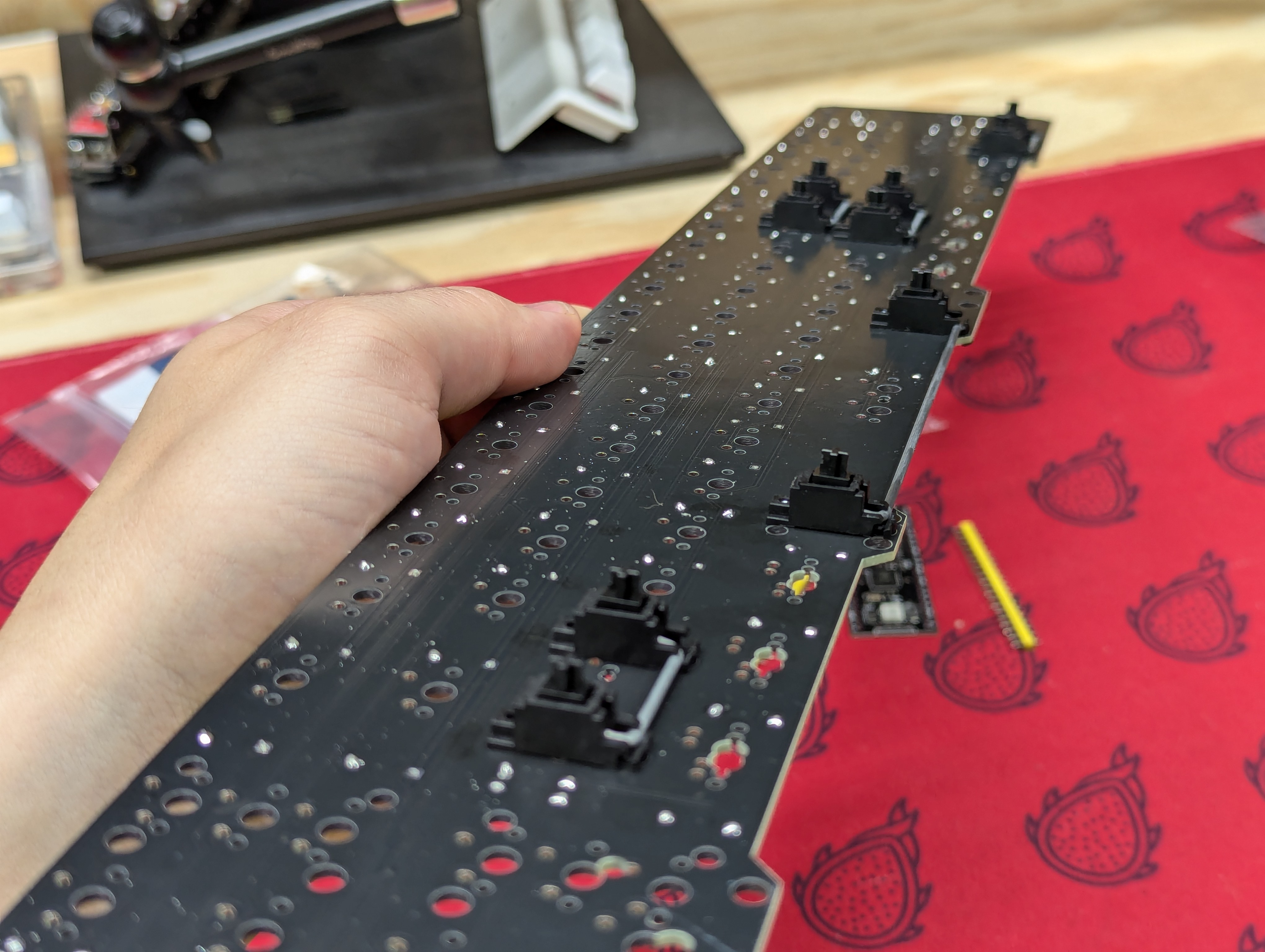

# Switches and Plate

The switches and the plate steps go together. It's your preference on the exact way to do it. If you're new to assembling keyboards, we recommend trying the order outlined

- Install a few switches into the plate.

- Install the plate and switches on the PCB, solder one lead of each switch if it's a soldered board.

Verify switches are sitting flush.

Insert the remaining switches into the plate.

finish soldering all the remaining switches.

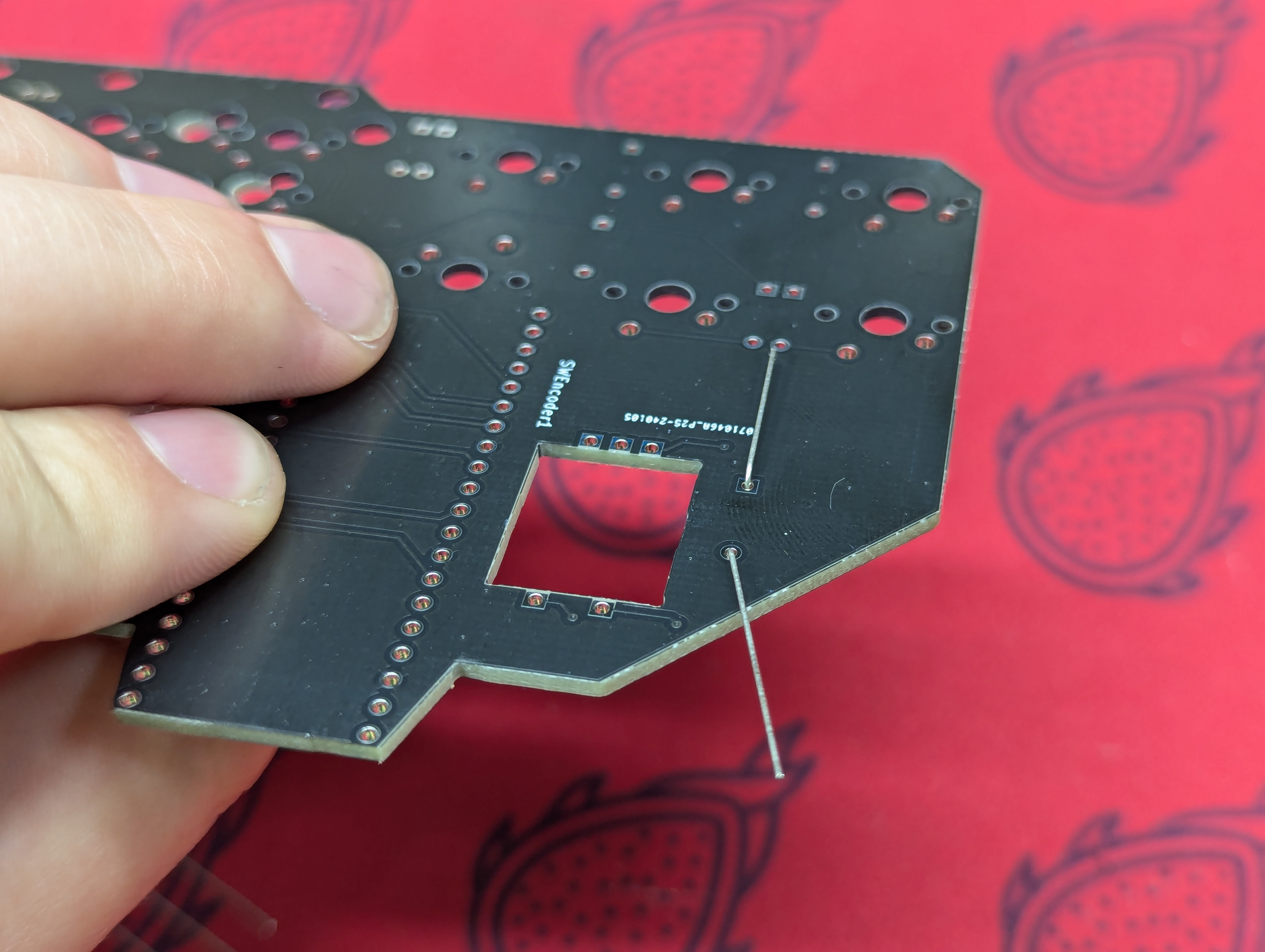

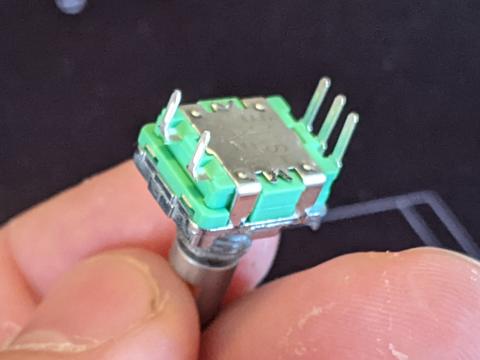

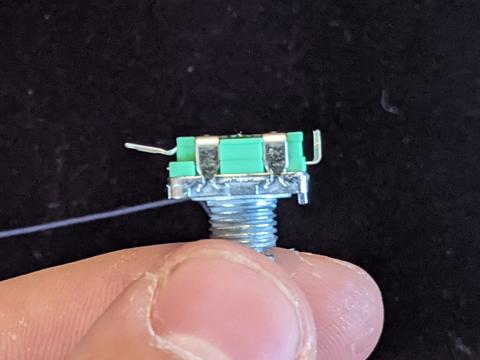

# Rotary Encoders

Next up is the rotary encoder. Prep the rotary encoder by snipping the mounting tabs with snips/flush cuts. Cut the set of 3 pins shorter so they are flush with the bottom of the rotary encoder. Lastly, bend the set of 2 pins so they are pointing straight out with a slight angle.

Place the rotary encoder in the hole of the top plate and hand tighten the washer and nut to hold it in place for soldering. Don't tighten this with any tools just yet. The washer has a slight bend in it so be careful to place the raised part in the center facing towards the front of the macropad. Use the pictures shown to ensure the correct orientation.

After the rotary encoder is in place, it is time to solder it. The 2 bent pins on the rotary encoder are resting just above the pads were they need to be soldered to, facing toward the switches. The 3 shorter pins on the rotary encoder are placed just to the side of the pads were they need to be soldered to. They do not go through the small holes. Take a look at the picture shown for a better explanation.

# Test the PCB

- Plug the finished MCU into the computer and open VIAL. Verify that each switch works by using the matrix tester in VIAL.

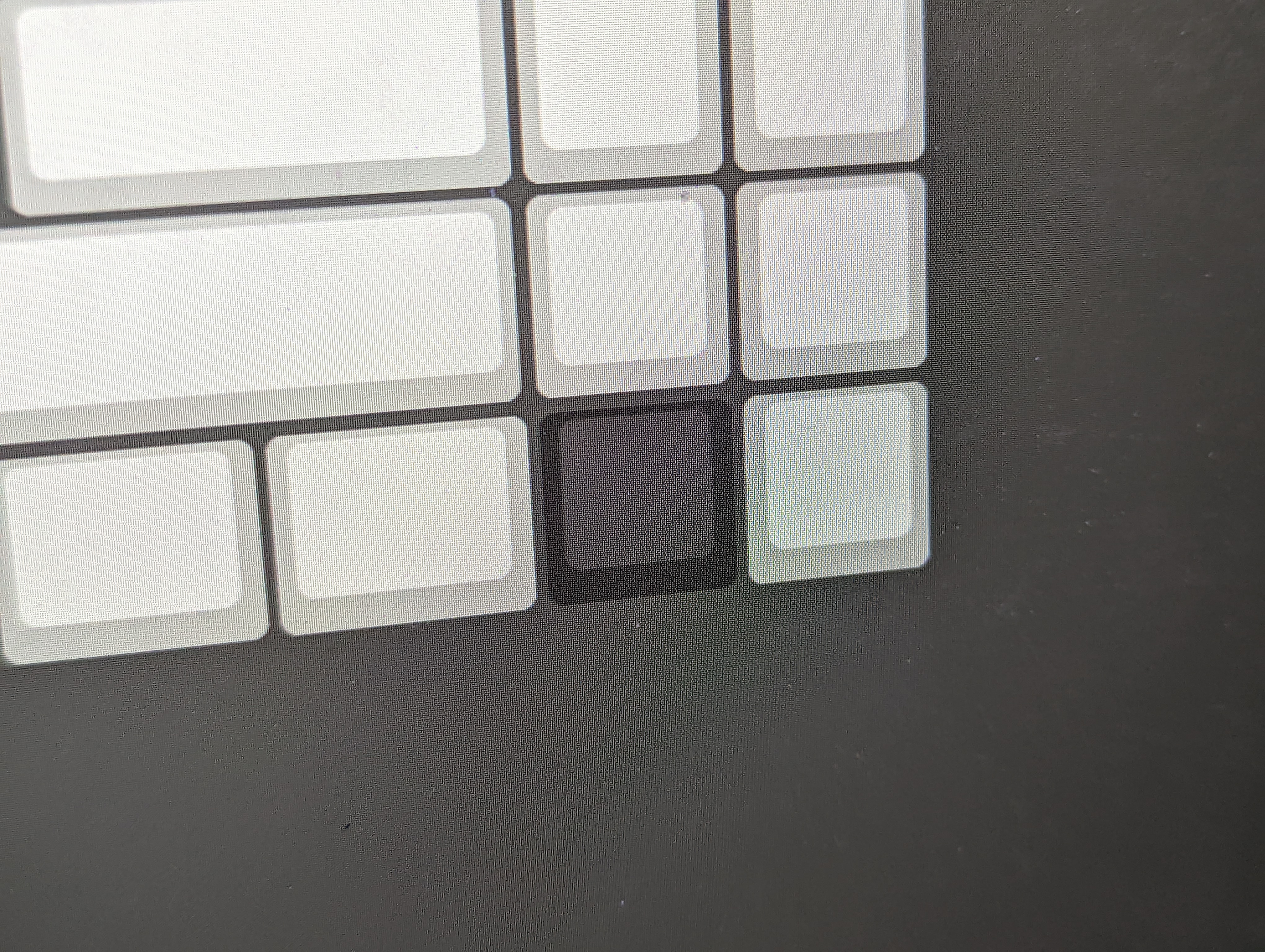

# Add gaskets

Add gaskets to the tabs of the plate on each side

# Assemble the Case

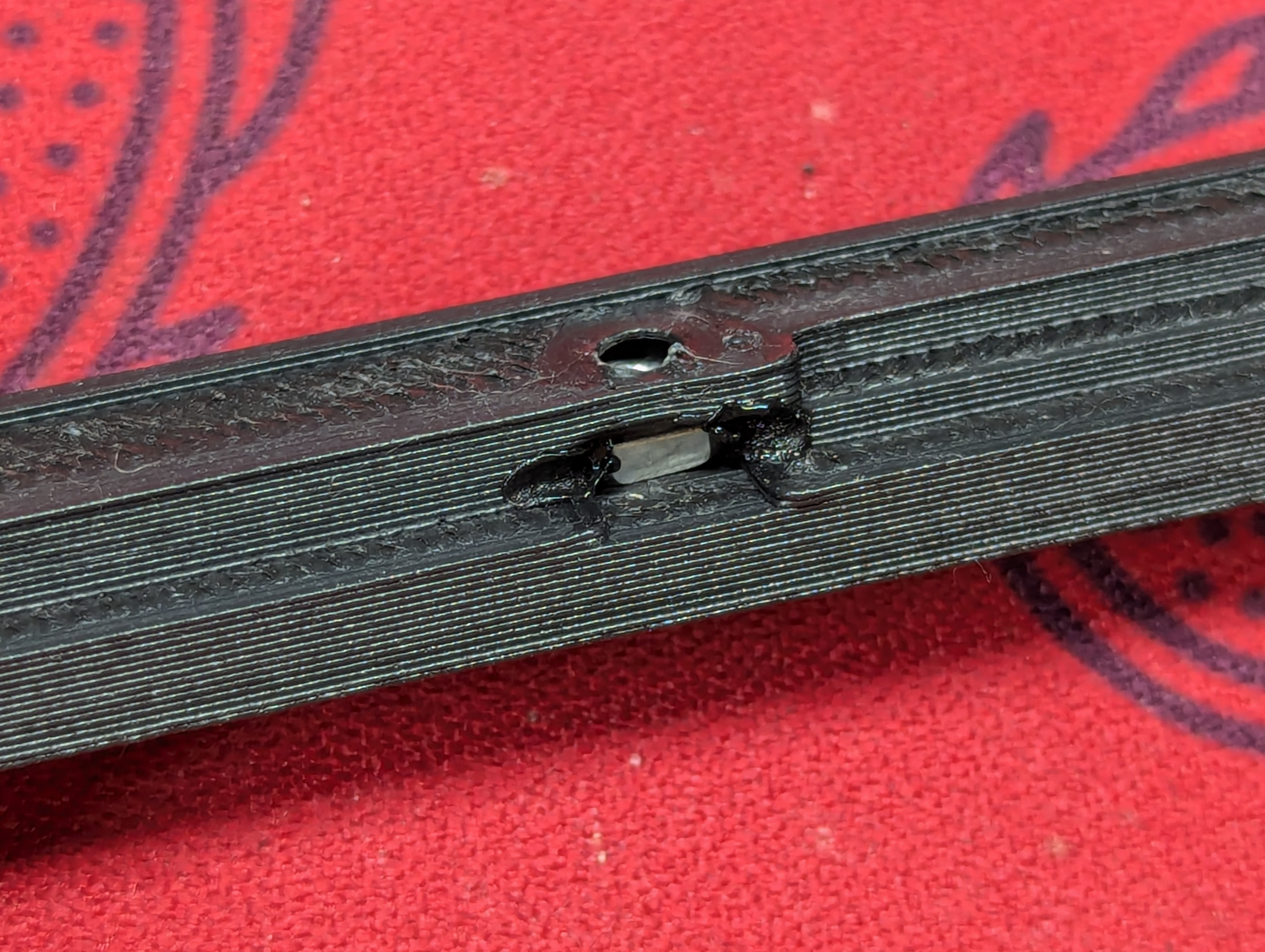

- insert M3 square nuts into top pieces. You will likely need to use something hard and pointy to insert the nuts into the print. They should be a press fit but if they slide out, you can use a soldering iron on the inside edge to help hold them in place.

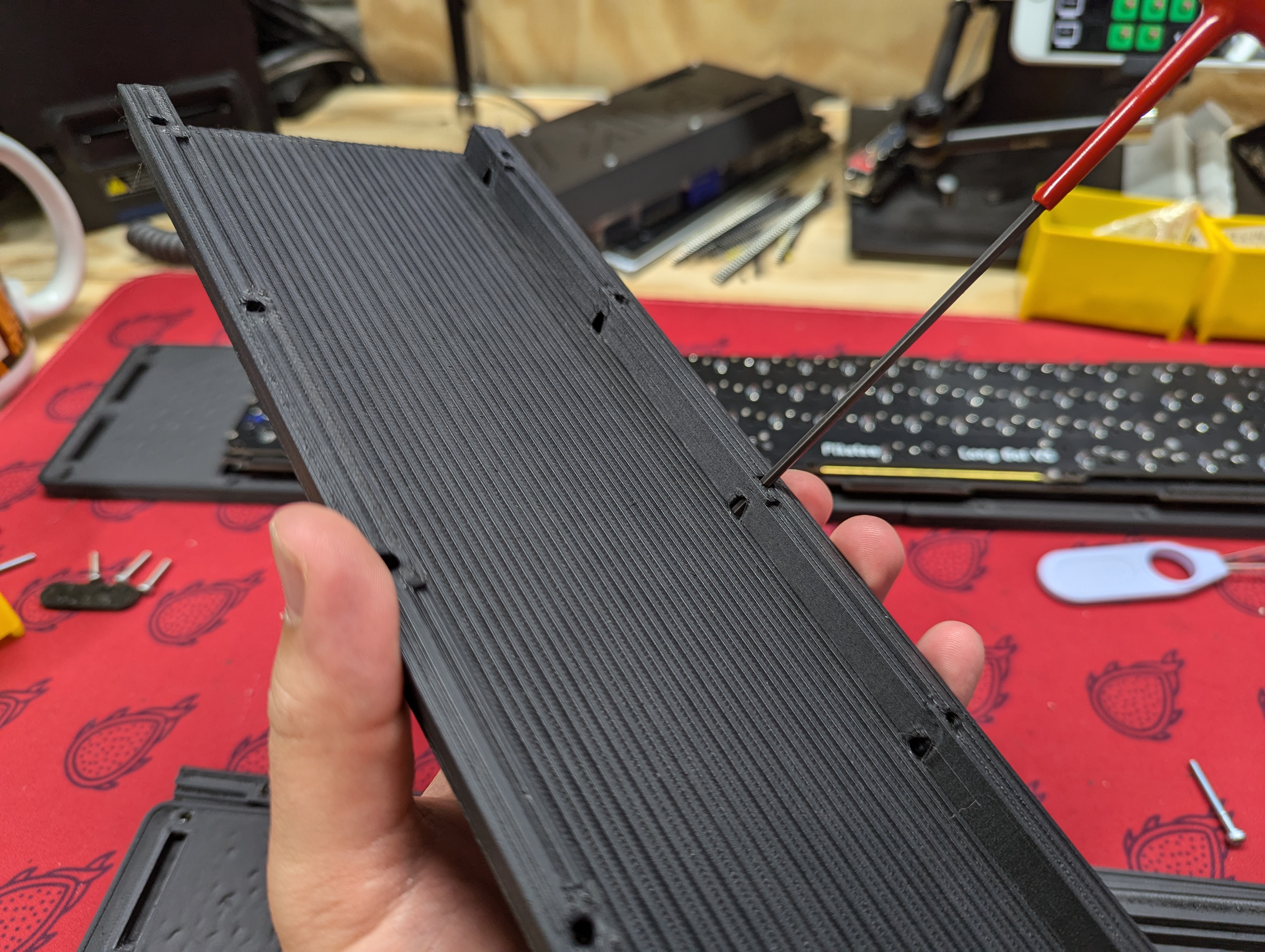

- Clean up the bottom peices. Bits of plastic resedue can be left inside the holes. Use a 2mm Allen wrench or similar to push the plastic and clear out the bolt holes. It's best if the bolts can be inserted into the pieces without any resistance.

- Attach the bottom middle to both top pieces. Get each bolt started before tighting them down. Even though there are square nuts and they won't strip, it's best to not over tighten. Error on the sie of too loose.

- Attach the side bottom pieces.

Extra. If you are struggling to get the bolts to thread into the square nuts, you can try aligning the square nuts slightly with a small allen wrench.

# Add the Keyboard Feet and Knob

Add the feet to the bottom of the keyboard and attach the knob the the encoder shaft.

# That's it!

- Celebrate. It's required.

Check out the programming guide to learn more about how to use your device.